A New Chapter in dvLED

Direct-view LED is a fantastic story of concept, evolution, and refinement… but someone needs to tell the tale.

Direct-view LED technology began its story on the biggest stages. Between pixel technology which offered only wide pitches (ergo further away viewers) combined with a cost-of-entry which was prohibitive to many spaces, direct-view technology was only realistically available in arenas, billboards, and certain high-profile spaces. Initial displays had poor power-balancing between their red, green, and blue elements resulting in massive power consumption. Initial dvLED also had limited viewing angles due to the early pixel-shader styles, which created discoloration and loss of image if you looked at a display from an oblique angle.

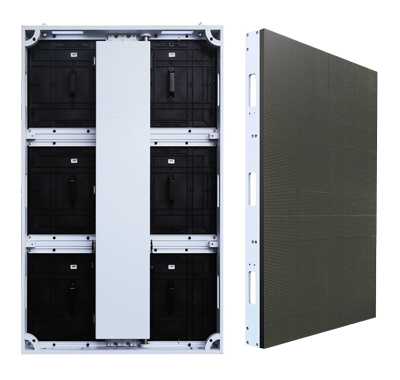

As direct-view technology has refined, so have the needs to implement it. The newest direct-view models boast fine pixel pitches, with robust and ruggedized pixel technology. Displays can run 24/7, while not emitting enough heat to require costly HVAC. Displays are light-weight, often requiring nothing more than a plywood backing for mounting, and a small handful of standard 110V circuits to power. This once mysterious and complex technology is now so modular and stable that many manufacturers now offer mobile cart options which sport full HD resolution, plugging into standard wall outlets.

In order to realize the full benefits which dvLED has over alternative display technologies, the conversation will need to eventually change. Direct-view technology deserves a new narrative from spokes-people familiar with the ease at which a variety of parts can quickly become a beautifully uniform and truly seamless display.

The best avenue to creating these technology evangelists is a simple certification, which can be earned in as little as three days. For many manufacturers, becoming certified requires an understanding of how data and power works with the technology, often including hands-on exercises. There are educational offerings out there to help installers get comfortable with the technology before jumping into a certification course. Almo Pro AV is offering a full dvLED installer education track at each stop of their 2020 E4 Experience. Certification in dvLED can be a powerful tool to becoming an ambassador, telling the story of a technology that does not require extraordinary mounting needs, complicated site-surveys, or extreme power handling capabilities.

Learn more about dvLED education opportunities at Almo Pro AV.